Michel’s Electric Roll Tarp Conversion

motor engaged

motor disengaged to operate crank

ELECTRIC UNITS

are available for both the Select and Maximize tarp systems. These electric units consist of a sealed 12V electric motor with a cover to prevent exposure to harmful elements. This motor is attached to an aluminum pivot arm that is mounted on the front of your truck box. This pivot arm holds the motor stationary so that just the motor shaft turns the roll tube to open and close your tarp system. This electric unit can be operated by using a rocker switch, mounted inside your cab or with an optional 210 Series Integrated Wireless Remote which will operate all Michel’s 210 Series Chute Openers, Convey Hawk , Convey Hawk II, Hopper Augers and Side Roll tarp systems as well as Lights and Swing Augers.

The “Original” Side-Rolling tarpaulin system with precise fit

OR

Incorporates added width to the fabric to accommodate heaped loads

FEATURES ON BOTH THE SELECT AND MAXIMIZER SIDE-ROLL SYSTEMS

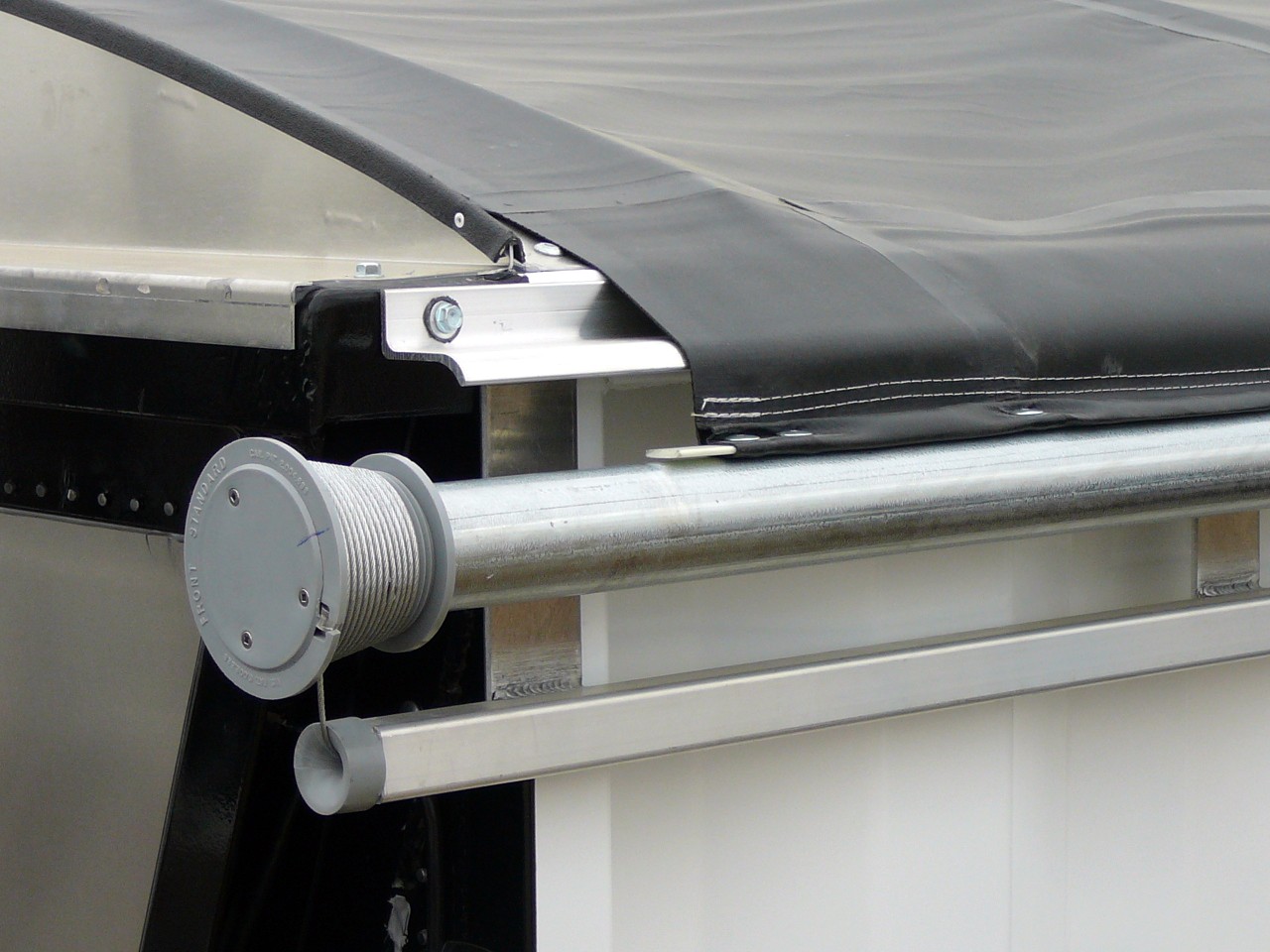

On both of these models, proven tension control using extension springs is incorporated along with bevelled pulleys on both ends to apply constant and uniform pressure. This “Hold-Back” device keeps the tarp rolling evenly during operation.

Farm models consist of a removable rear hood/end cap that enables the full function of the tailgate.

A fiberglass ridge poll, sewn into a pocket on the fabric, is used to support the baric between the cross-members. This procedure is optional for semi trailer units, some trailers have their own rod running down the centre of the trailer.

Semi trailer units have the option of a front or rear crank that can be either short (2’6″) or long (8′). The crank length is adjustable to suit your trailer or operator.

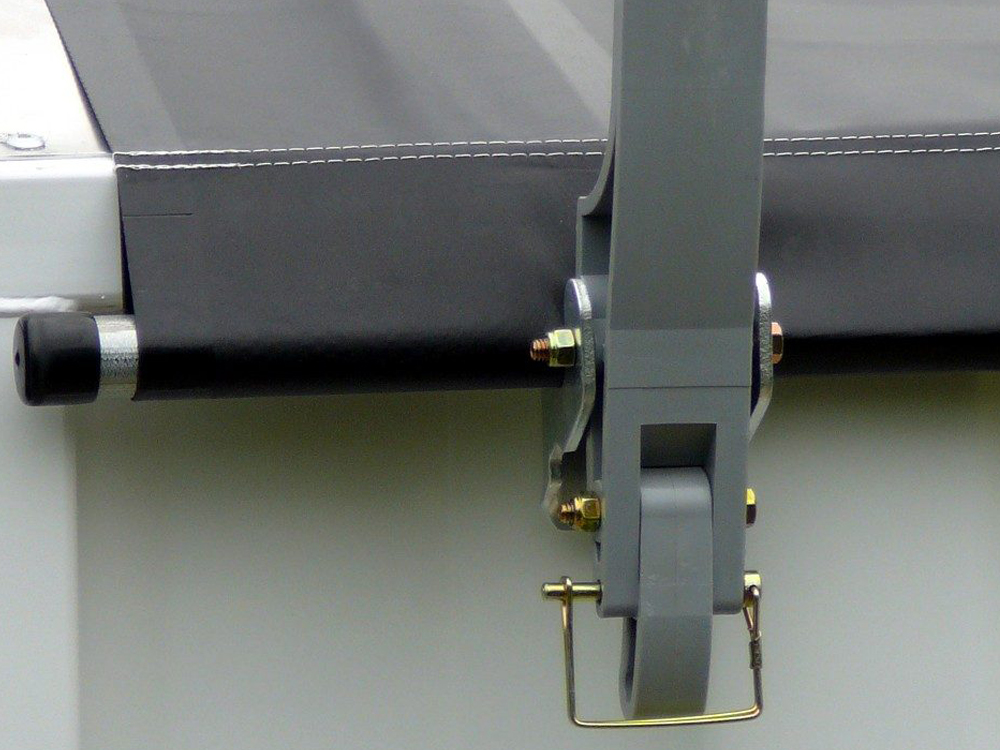

Built on style, tarp stops are standard on all Side-Rolling Tarpaulin Systems.

Optional “Flip Release” tarp stops are offered for all side-rolling tarp systems. These “Flip Release” tarp stops are available with a 3″ or 6″ offset which allows clearance of the box or trailer.